Global brands frequently rely on Original Equipment Manufacturing to scale their operations and maintain market competitiveness. Following a structured oem production guide is essential for navigating the complexities of offshore manufacturing. This model allows companies to design unique products while outsourcing the actual fabrication to specialized factories. However, success requires meticulous planning, clear communication, and robust quality control measures.

The journey from initial design to final delivery involves multiple stakeholders and potential risks. Managing these variables effectively determines the ultimate profitability of a product line. Consequently, experienced importers prioritize strategic partnerships to oversee the technical aspects of production. We explore the critical phases of the manufacturing cycle and the professional support needed for success.

Defining the OEM Manufacturing Model

Original Equipment Manufacturing involves a factory producing goods based on the specific designs and requirements of a buyer. In this relationship, the buyer retains ownership of the intellectual property and brand identity. The manufacturer focuses exclusively on the technical execution and assembly of the product. This distinction is vital for brands seeking to offer unique items in a crowded marketplace.

Understanding the technical boundaries of this model helps organizations allocate their resources effectively. While the factory provides the machinery and labor, the buyer must provide precise technical documentation. This collaboration ensures that the final output aligns perfectly with the brand’s vision and quality standards. Thus, the model bridges the gap between creative design and industrial capacity.

The Vital Role of a Procurement Agent

A procurement agent acts as a local representative for the buyer within the manufacturing region. They provide the necessary physical presence to oversee production in real time. This role is especially critical when dealing with language barriers and different business cultures. They serve as the primary link between the design team and the factory floor.

Strategic Roles in Factory Oversight

The primary role of the agent is to verify that the factory adheres to the agreed specifications. They visit the facility regularly to monitor progress and identify potential bottlenecks early. Furthermore, they ensure that the raw materials used meet the required safety and durability standards. This constant oversight is a core element of any professional oem production guide.

They also handle the logistical coordination of samples and prototypes between the factory and the buyer. This iterative process ensures that all design flaws are corrected before mass production begins. By acting as a technical liaison, the agent prevents costly misunderstandings and production delays. Their presence creates a culture of accountability within the manufacturing facility.

Responsibilities of a China Procurement Agent

A China procurement agent manages operations in the world’s most complex and diverse manufacturing landscape. They identify specialized factories that possess the specific machinery needed for complex product designs. Moreover, they conduct rigorous background checks to ensure the factory is a legitimate and stable business entity. This vetting process is essential for protecting the buyer’s financial investment.

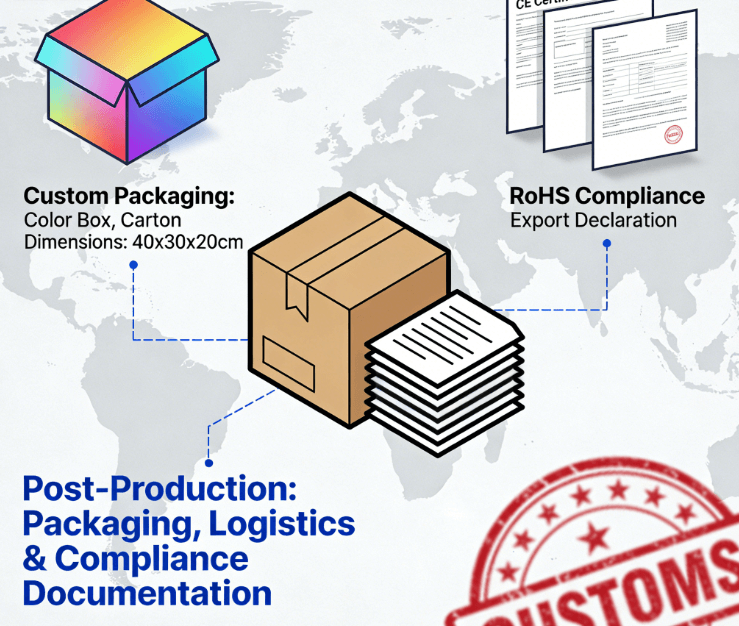

The agent also manages the negotiation of pricing and payment terms in the local currency. They understand the actual market costs of components, allowing them to secure fair and competitive rates. Additionally, they handle the collection of all necessary export documentation and compliance certificates. Their comprehensive management ensures a seamless transition from the assembly line to international shipping.

Core Functions in the Production Cycle

A successful manufacturing project follows a series of disciplined steps to ensure quality and consistency. Each phase requires specific attention to detail and proactive problem solving.

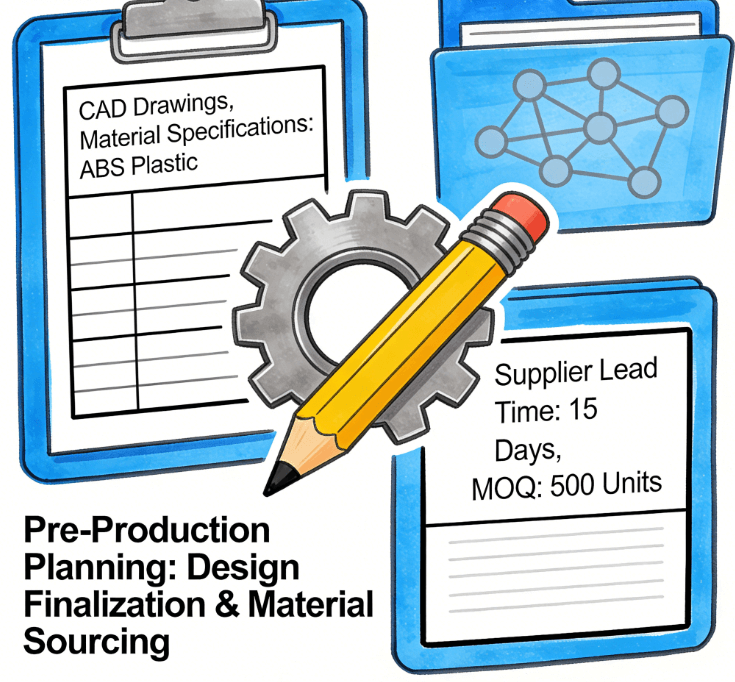

Technical Documentation and Sampling

The process begins with the creation of detailed technical files, including blueprints and material specifications. A procurement agent reviews these files with the factory’s engineering team to ensure feasibility. Following this, the factory produces a golden sample for the buyer’s final approval. This sample serves as the benchmark for all future production units.

Any discrepancies found during the sampling phase must be addressed and documented immediately. This phase is the last opportunity to make design changes without significant financial impact. Therefore, the agent plays a crucial role in validating that the prototype meets every functional requirement. Precise sampling is the foundation of a reliable supply chain.

Quality Control and Inspection Protocols

Maintaining consistent quality requires a systematic approach to inspections throughout the manufacturing process. The agent performs initial production checks to verify that the first batch meets the approved sample. They also conduct in-process inspections to identify any emerging defects on the assembly line. These proactive measures prevent the accumulation of faulty products.

The final pre-shipment inspection is the most critical step in the oem production guide. The agent verifies a random sample of the finished goods against the quality checklist. They check for functional defects, aesthetic flaws, and packaging accuracy. Only after the goods pass this rigorous review should the buyer authorize the final payment.

Strategic Advantages of Professional Support

Utilizing professional sourcing support provides measurable benefits that enhance a brand’s competitive position. These advantages focus on risk mitigation, cost optimization, and operational speed.

Enhanced Risk Management

Manufacturing overseas involves inherent risks, including fraud, quality fade, and intellectual property theft. A procurement agent mitigates these risks by acting as a local enforcer of the buyer’s interests. They ensure that the factory follows all security protocols to protect sensitive design data. Their regular physical presence discourages the factory from cutting corners or using sub-standard materials.

Furthermore, the agent provides early warnings about potential disruptions, such as local power shortages or labor strikes. This market intelligence allows the buyer to adjust their inventory plans proactively. Having an expert on the ground turns a high-risk venture into a manageable strategic asset. Risk mitigation is the primary value proposition of professional sourcing services.

Improved Cost and Time Efficiency

A local agent uses their market knowledge to identify the most cost-effective suppliers without compromising quality. They negotiate better rates for raw materials and components by leveraging their existing factory relationships. Consequently, the buyer achieves a lower total cost of ownership for their product line. These savings directly contribute to the brand’s bottom line.

Professional agents also accelerate the production timeline by managing the factory’s schedule more effectively. They resolve technical issues on the spot, preventing long delays caused by remote communication. This speed to market is essential for capturing seasonal demand and reacting to consumer trends. Efficiency in both time and cost is a hallmark of an expert oem production guide.

How to Find a Reliable Sourcing Partner

Finding the right agent is just as important as finding the right factory. Buyers must use a systematic vetting process to ensure they select a partner with high integrity and expertise.

Assessing Industry Experience and Reputation

Begin by looking for a China procurement agent who specializes in your specific industry. Different product categories, such as electronics or textiles, require very different technical knowledge. Ask for detailed references from current clients who have similar manufacturing needs. A reputable agent will be transparent about their previous successes and challenges.

Evaluate their office infrastructure and the size of their quality control team. A reliable partner should have a physical presence near the major manufacturing hubs relevant to your product. Their ability to reach the factory quickly for surprise inspections is a significant advantage. Experience and local presence are non-negotiable criteria for a sourcing partner.

Evaluating Communication and Fee Structures

Clear and timely communication is essential for a successful long-distance partnership. The agent must provide regular reports with photos and videos of the production progress. They should use organized digital systems to track all samples, inspections, and shipping documents. Transparency in communication builds the trust necessary for a long-term relationship.

Avoid agents who offer their services for free, as they likely take hidden commissions from the factory. A professional agent charges a transparent service fee or a percentage of the total order value. This structure ensures that their interests remain perfectly aligned with those of the buyer. Ethical fee structures are a sign of a professional and reliable partner.

Common Mistakes in OEM Production

Even experienced brands can fall into common traps that lead to manufacturing failures. Awareness of these pitfalls is a critical part of any oem production guide.

Incomplete Specifications and Ambiguity

Providing vague or incomplete product specifications is a leading cause of manufacturing errors. Factories will often make assumptions to fill in the gaps, which may not align with the buyer’s expectations. Every detail, from the type of screw used to the thickness of the coating, must be documented. Clear specifications eliminate the room for manufacturer discretion.

A procurement agent reviews these documents to ensure they are technically sound and understandable for the local engineers. They translate complex requirements into actionable instructions for the factory floor. Eliminating ambiguity is the most effective way to prevent mass defects. Precision in documentation is a key best practice.

Neglecting On-Site Quality Oversight

Relying solely on the factory’s internal quality reports is a major risk for international buyers. Factories may be tempted to overlook minor issues to meet strict shipping deadlines. Without independent verification, the buyer has no way of knowing the true quality of the goods. This lack of oversight often leads to receiving sub-standard products.

Always mandate that a China procurement agent or a third-party inspector performs a final check. This inspection must happen before the goods are loaded into the shipping container. Seeing the goods in person is the only way to guarantee they meet the brand’s standards. Physical oversight is the ultimate quality assurance tool.

Practical Case Study: Scaling Product Launch

A boutique home appliance brand in Europe wanted to launch a custom espresso machine. They had a unique design but struggled to find a factory capable of meeting their high-pressure pump requirements. They hired a specialized procurement agent to manage the project. The agent followed a strict oem production guide to find a high-tech factory in southern China.

The agent oversaw three rounds of prototyping to perfect the internal water flow system. During mass production, the agent discovered a batch of faulty heating elements and ordered an immediate replacement. This intervention prevented the brand from launching a defective product that would have damaged their reputation. The espresso machine became a bestseller, proving the value of expert local management.

Strategic Value of Integrated Manufacturing

A well-managed manufacturing partnership provides a scalable platform for long-term brand growth. It allows companies to expand their product catalog without the massive capital expense of building their own factories. This flexibility is a vital strategic advantage in a rapidly changing global economy.

By integrating professional sourcing into their business model, brands can focus on high-value activities like marketing and innovation. The procurement agent handles the operational complexity, ensuring a steady flow of high-quality goods. This synergy creates a resilient and agile supply chain that can adapt to any market condition.

Future Trends in Modern Sourcing

The future of manufacturing will be defined by digital transformation and a focus on social responsibility. These trends are changing how buyers, agents, and factories collaborate.

Digital Transparency and Real-Time Tracking

Advanced factories are implementing digital monitoring systems that allow buyers to see production data in real time. Procurement agents use these platforms to track every stage of the assembly process remotely. This level of transparency reduces the need for manual reporting and increases trust between all parties. Digital integration is the next frontier of the oem production guide.

Future systems will use blockchain to create a permanent record of all quality inspections and material origins. This will provide total traceability, allowing brands to prove the authenticity and safety of their products. Real-time data will make global manufacturing faster and more secure than ever before.

Sustainability and Ethical Compliance

Consumers are increasingly demanding that products be made in an environmentally and socially responsible manner. Consequently, factories must adopt green energy and fair labor practices to remain competitive. A China procurement agent plays a critical role in auditing factories for these sustainability standards.

Ethical sourcing is becoming a mandatory requirement for entering major international markets. Brands that prioritize these values will build stronger relationships with their customers. The shift toward responsibility is a fundamental change in the global manufacturing landscape. Sustainability is now a core component of long-term business value.

Conclusion: Mastering the Manufacturing Cycle

Building a successful brand through Original Equipment Manufacturing requires a disciplined and expert approach. A comprehensive oem production guide provides the roadmap for navigating the journey from design to delivery. By leveraging the local expertise of a procurement agent, organizations can mitigate risks and optimize their entire supply chain. Focus on technical precision, rigorous quality control, and ethical partnerships to secure a dominant position in the global market. The investment in professional sourcing support is the key to achieving sustainable manufacturing success.

FAQ for Manufacturing Success

Q1: What is the difference between OEM and ODM?

OEM involves manufacturing a product based on the buyer’s unique design and specifications. ODM, or Original Design Manufacturing, involves the factory designing the product themselves and the buyer simply adding their brand. OEM offers more creative control while ODM is faster for market entry.

Q2: How do I protect my design from being copied?

You should have the factory and your China procurement agent sign comprehensive Non-Disclosure and Non-Circumvention agreements. Additionally, work with vetted factories that have a reputation for respecting intellectual property. Regular factory visits by your agent also help monitor that your designs are not being used for other clients.

Q3: What should I do if the final products are defective?

Your contract should include clear clauses regarding defect resolution and financial penalties. If your procurement agent identifies defects during the final inspection, you should refuse to authorize payment until the factory corrects the issues. Having a local agent allows you to negotiate these repairs or replacements directly on the ground.